Nachi America Divisions

Welcome to Nachi America

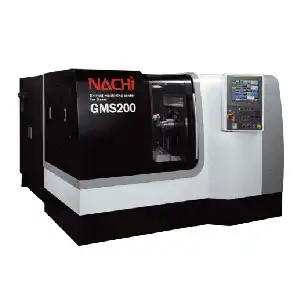

Nachi is a worldwide manufacturer of innovative products: bearings, precision cutting tools, hydraulic equipment, machine tools, robots and high speed steel. We are proud to deliver products manufactured to the highest possible standards and maintain an ongoing commitment to incredible quality.

Integrated Excellence

At Nachi, we develop technology for both product and process. Spanning from specialty steels used in the manufacture of cutting tools and bearings to the equipment used in their manufacture and beyond, to the equipment that is used by our customers in their manufacturing facilities. Also, as an OEM supplier of bearings and hydraulics we touch directly to the ultimate end user of our customers products. We control every facet of the manufacturing processes and our manufacturing equipment and processes are utilized worldwide.

![Nachi America [Home]](/img/NachiAmerica_logo.svg)