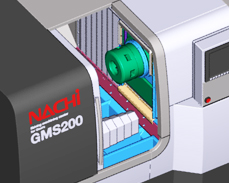

Skiving Machining Center for Gears GMS200

General purpose·Compact Multi-function machine to include skiving function

- Best for gear machining for automotive parts.

- Compact equipment with flexibility to cope with the various kinds of small quantity production and multiple processes.

- Hard-skiving achieves high-precision machining of hardened gears

- Interactive operation screen provides excellent man-machine interface

Overview

Main text

Skiving machining center for Gears GMS200

|

General purpose·Compact Multi-function machine to include skiving function

|

Features

Main text

Skiving machining center for Gears GMS200

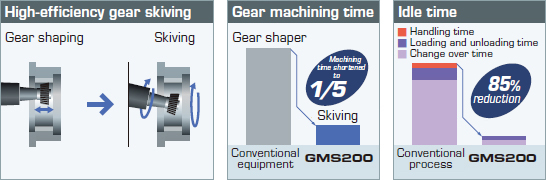

High-efficiency gear skiving and integrated process

remarkably reduce machining time

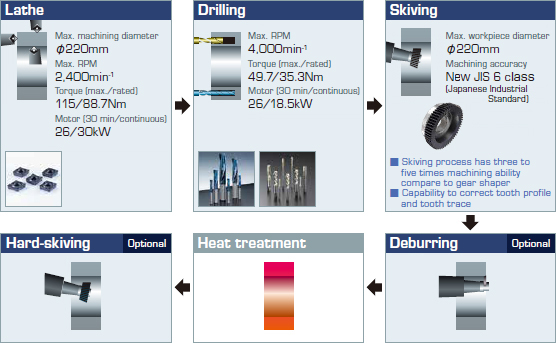

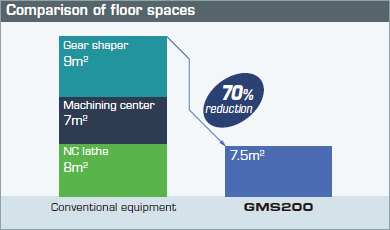

Multiple process in one machine

To achieve compact production lines by reducing floor space

with 3 roles in 1 machine

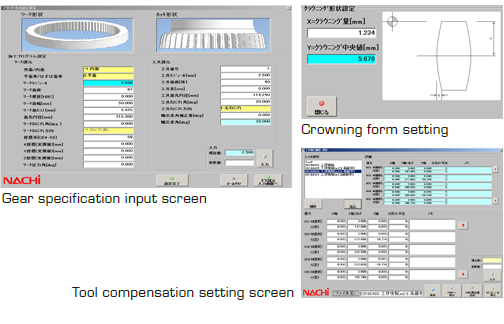

Superior workability and operability

Interactive operation screen for skiving (optional)

- Crowning process and run-in amount modification function (initial mode)

- Newly added tool compensation setting and workpiece coordinate system preset

All machining conditions for skiving can be set

Ceiling opening door

- Aperture dimension : 600mm

- Easy access to jig and simple loading & unloading of workpieces

- Workpiece installation

height : 1,170mm

Reduced machine height for better view

- Contribute to environment improvement in factory

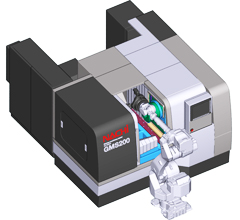

The design for auto loading system with robots

Machining application

Internal gear

External gear

Spline

Skiving cutter for hard-skiving

- Achieved high precision of workpieces after heat treatment

- The design reduces noise from reducer

- NACHI's original DuAl Hard coating for hard skiving

- Stable machining without rake face coating

Combine with NACHI robots

Combine with NACHI robots for auto loading system

MZ04

EZ03

MZ12

Specifications

Main text

Skiving machining center for Gears GMS200

Main specification

| Machining capacity | Max. workpiece diameter | mm | Ø220 |

|---|---|---|---|

| Gear cutting tool | — | Skiving cutter | |

| Cutter spindle | Spindle taper hole (tool shank type) |

— | KM6350 |

| Max. RPM of spindle | min-1 | 4000 | |

| Motor (30 min/continuous) | kw | 26/18.5 | |

| Workpiece spindle | Max. RPM of spindle | min-1 | 2400 |

| Motor (30 min/continuous) | kw | 26/30 | |

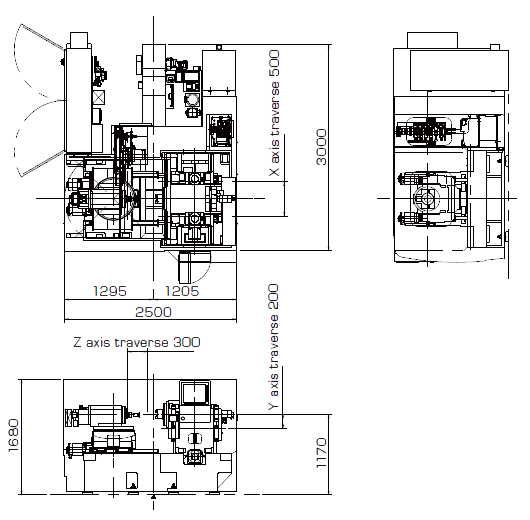

| Each unit traverse | Left-Right traverse (X-axis) | mm | 500 |

| Forward-Back traverse (Y-axis) | mm | 200 | |

| Up-Down traverse (Z-axis) | mm | 300 | |

| Tool swivel angle (B-axis) | deg | ±45 | |

| A.T.C. | Number of tool storage | piece | 6 |

| Max. tool diameter | mm | Ø120 | |

| Max. tool length | mm | 240 | |

| Tool selection method | — | Tool storage position fixed/random | |

| NC device | Type | — | FANUC 31i-B |

| Display | — | FANUC 15" touch panel | |

| Utilities | Overall power used | kVA | 74 |

| Dimensions of machine | Machine height | mm | 1680 |

| Required floor space (width × depth) |

mm | 2500 × 3000 | |

| Net machine weight | kg | 7000 |

Layout diagram

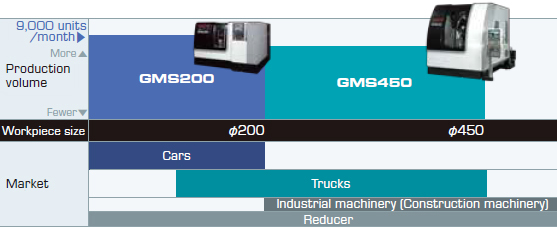

Product line-up for ring gear machining

![Nachi America [Home]](/img/NachiAmerica_logo.svg)