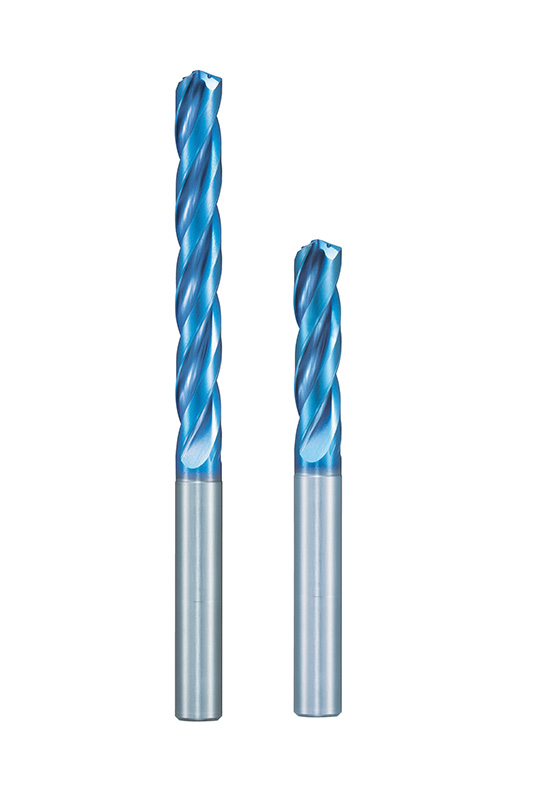

AQUA DRILL EX OIL HOLE 3 FLUTE

- High precision drilling as deep as 5xD

- High accuracy achieved at high feed rates with an optimized cutting-edge form and the superior drilling balance of 3-flutes

- Multi-layered Aqua Ex Coating (TiALN+TiAlCr)

- Anti-adhesive coating film for added lubrication

- Suitable for wide work materials like Carbon Steels, Alloy Steels, and Stainless Steels

Outline

Main content

AQUA Drill EX 3 Flutes Regular

|

High-accuracy drilling

|

Catalog Download

![]() Catalog No. 2232-3 AQUA Drill EX 3 Flutes (24 pages/3,017 KB)

Catalog No. 2232-3 AQUA Drill EX 3 Flutes (24 pages/3,017 KB)

The listed price applies to consumers in Japan.

Features & Performance

Main content

AQUA Drill EX 3 Flutes Regular

A 3-flute drill with an optimized flute geometry and cutting-edge design for an excellent cutting balance

|

High-accuracy drilling

|

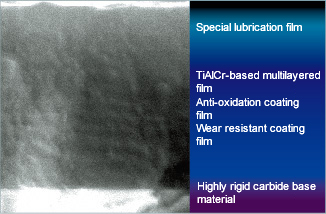

AQUA EX coating with enhanced resistance to heat and wear

AQUA EX coating

- Features a special lubrication film and smoothing treatment for excellent chip evacuation

- Ensures high oxidation resistance (1,100°C) by adding a layer with high Al content

- Controls crack propagation with a multilayered structure. Optimizes compressive strength for increased film hardness (3,300HV).

Increases resistance to wear.

Oxidation resistance evaluation

Competitor products (listed oxidation resistance at 1,200°C) Total oxidation |

AQUA EX coating Approx. 50% oxidation |

Applicable work materials

|

Low-carbon steels SS400, S10C |

Carbon steels S45C, SCM440 |

Pre-hardened steels SUJ, NAK |

Tempered steels SKD, SKH |

Hardened steels Hardened steels |

|

|---|---|---|---|---|---|

| 30 |

40 |

50 |

|||

|

Stainless steels |

Heat-resistant alloy Ti/Ni Alloys |

Cast iron FC/FCD |

Aluminum alloy AC/ADC |

Copper/copper alloy Cu |

|

| SUS304 | SUS420 | ||||

| × | × | × | × | ||

![]() : optimal

: optimal ![]() : applicable ×: not applicable No mark: not recommended

: applicable ×: not applicable No mark: not recommended

List Numbers

AQUA DRILL EX OIL HOLE 3 FLUTE LIST NUMBERS

9826 - 3D, Metric sizes

9820 - 5D, Metric sizes

![Nachi America [Home]](/img/NachiAmerica_logo.svg)